| CATEGORY | Architecture Tertiary sector |

| TIPOLOGY | Tourism Restoration |

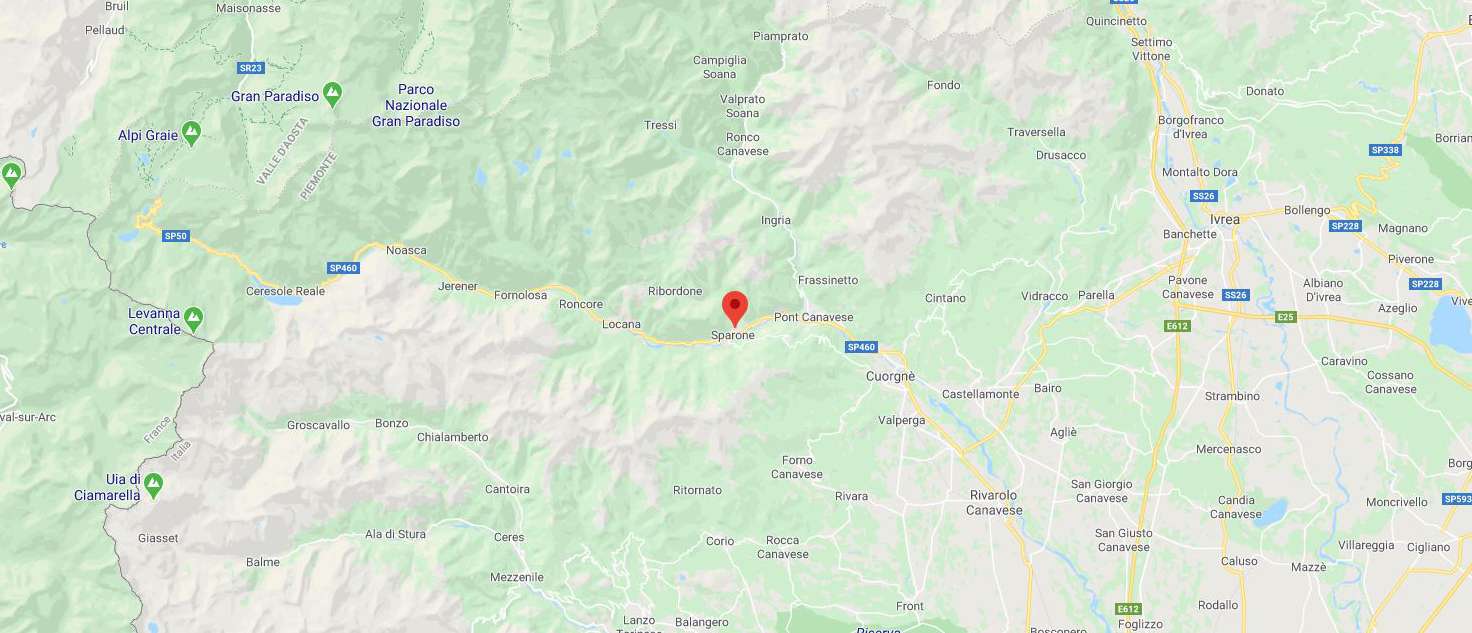

| PROJECT | Antica Fucina dei Mestoli di Sparone /Ancient Ladles’ Forge of Sparone, Turin. |

| CLIENT | Municipality of Sparone (Tturin) |

| PLACE | Sparone (Turin) |

| YEAR | 2019 - 2020 |

| SQUARE | 100 mq |

| STATUS | completed |

In the historical core of Sparone, behind the Parrocchiale di San Giacomo (the parish church of St James), Sertec was commissioned by the Municipality to finally reopen the doors of a valuable evidence of an ancient copper processing: l’antica Fucina dei Mestoli (the ancient Ladles’ forge).

The former factory, closed for decades, has substantially kept intact its historical architecture, composed of two dusty rooms with a barrel vault, on the ground floor of a humble 16th century building. The floor is paved with stone and made of rammed earth, the walls and vaults are all made of sooty stone, roughly plastered; at the side of the two rooms a typical covered passage with a barrel vault insists and it allows the access to the courtyard of relevance.

The charm that pervades the forge is not limited to its “immaculate” historical architecture but it extends to its interior layout. In fact, the rich collection of original tools and machinaries, some of which date back to the 16th century, is the extraordinary secret that proudly gards the former factory.

“La Fucina dei Mestoli” (The Ladles’ Forge”) is bound by the Superintendence pursuant to the articles 10,12 of the Legislative Decree 42/2004. It is well suited for a use in favor of the community for the development of a small ecomuseum thanks to its interesting layout, its particular architectural typology and its location in the historical center. It is a new cultural center for the permanent exhibition of material knowledge and typical local workmanship, aiming at the protection and enhancement of the network of “minor” cultural heritage spread in the inhabited buildings of the Orco Valley.

The project signed by Sertec was to realize works aimed at preserving the historical architecture, restoring the tools- with the support of Mauro Barolat Luisa, a restorer originally from Ivrea and, at the same time, it aimed at adapting the building to its new function as a new municipal ecomuseum thus improving the use of its spaces.

Considering the complexity of the existing layout and the irregularity of the building elements (vaults, walls, floors, doors and windows) it was useful to carry out a survey with laser scanner technology. This inspection was done in order to obtain an exact architectural survey and a better cataloguing of the assets. This cataloguing was coordinated by the Department of historical Studies of the University of Turin.

PLEASE NOTE:

The presentation images show in order: the ante operam Fucina dei Mestoli (Ladle Forge), the graphical elaborations of the point cloud detected by laser scanner during the design phase, the post operam Fucina (Forge).

HISTORICAL NOTES:

Upstream from the historical center of Sparone, from the locality known as Sommavilla and down to the lower part of the village, near the course of the so-called “Roggia delle Fucine” o “Roggia del Mulino”, several mills for grinding grain and several forges for copper processing were active as early as 1500, that is craft workshops that continued their work over the centuries.

Inside the sooty walls of the forges of Sparone, the forges were activated by long and sinuous air ducts. This air was formed by the fall of water, the so-called “hydroeolic trumpet” where in the basin by the vertical fall of water, the air used to foment the burning coals formed. The show became unique: the copper melted in the crucibles took on a red colour and was surrounded by an infinity of sparks. Then, with a big ladle, the copper was poured into many refractory earthen cups. The “magnin” or the coppersmith, that is the craftsman who worked the copper, promptly sprinkled the tiles with sand and as soon as they solidified he passed them on to his companion, who was crouched next to the mallet with his feet wrapped in rags soaked in water mixed with refractory earth to evade the heat. Then the cauldronmaker lit giving free rein to the waters of the irrigation ditch deriving from the nearby stream known as Ribordone. The mallet, a portentous and enigmatic empirical machine, intermittently struck the ground with its pointed head and the “magnin”, thanks to his pliers, rotated the piece that was still hot gaving it the desired shape. The artifacts were reduced to a certain thickness and then they were hammered in several sheets together in order to form the rough pieces that through the ingenious hands of the batters were transformed in valuable cantilever works.